This three day weekend started off, as I posted two days ago, with picking up the engine. That wasn’t the only work I got done this weekend, however. Although this ended up another weekend where I seemed to spend more time in stores than working on the car, I made some good progress. Read more for details and (hopefully) photos.

What exactly I wanted to do this weekend changed as the weekend progressed. Getting the motor quite a bit earlier, I thought actually getting it in the car would be good. Its in the way right now, and it would make working in the garage much easier if it was actually in the car. I also figured I could start working on the fuel lines.

As it turned out, I didn’t have a good way to get the engine into the car. Its been a long time since I’ve done something like that and I really want someone here who knows what they’re doing. I posted on FFCobra’s forums but with one day notice I was unable to find anyone who could come help. Hopefully in two weeks I can get a couple guys here to give me a hand and make sure I don’t screw anything up.

Given that, I decided I should work on the fuel lines. While waiting for PepBoys to open for yet another trip to a parts store this weekend, I stopped at Home Depot and picked up some metal stock figuring I could use it at some point to fabricate a bracket for the brake reservoirs, as well.

First things first, I should mention its important to make sure you don’t leave metal stock sitting on shelves sticking out, particularly in ways that keep them from moving if you were to, say, ram yourself into it.

Yeah. That hurt. A lot.

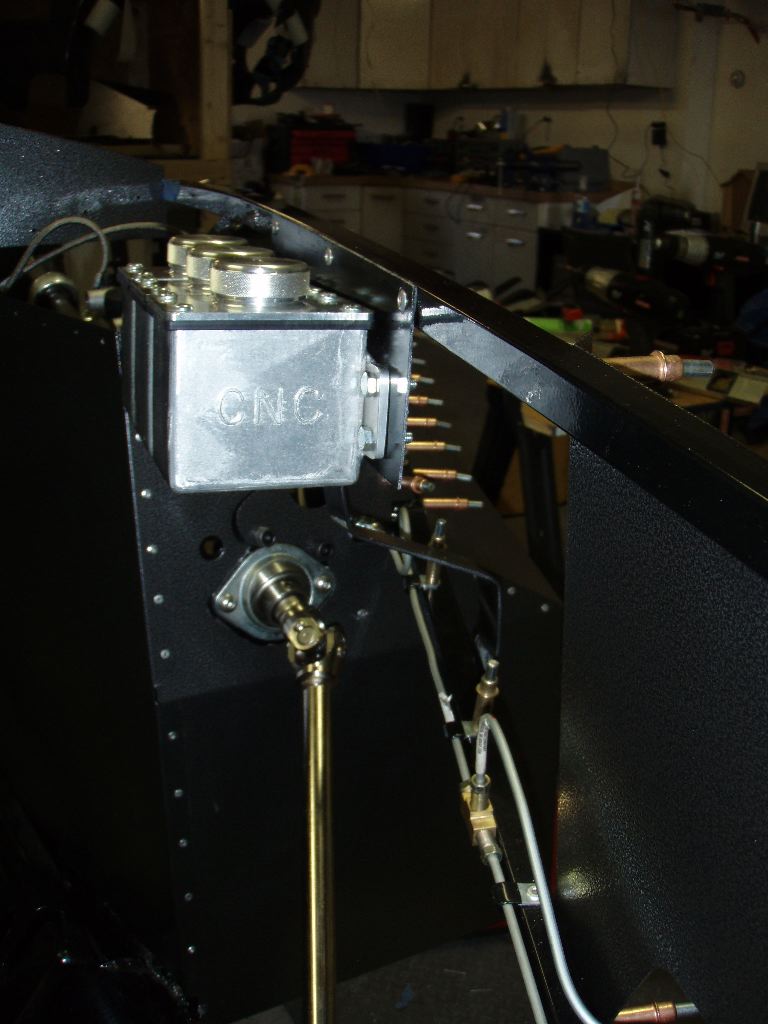

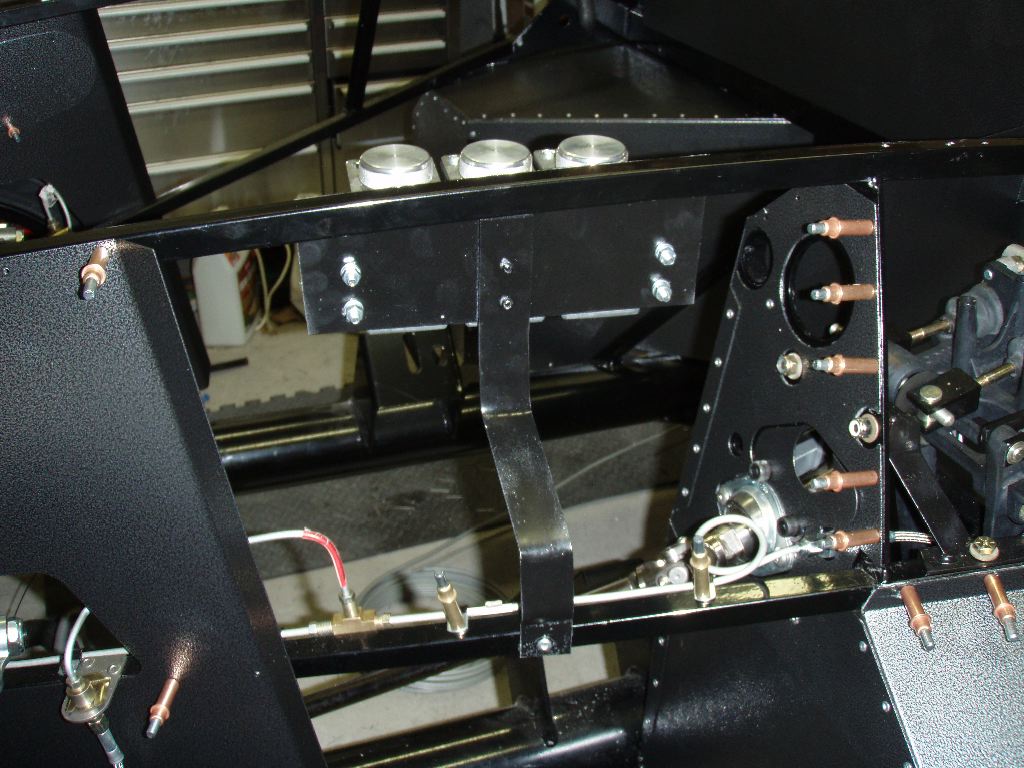

So two trips to Pep Boys and two trips to AutoZone, plus a trip to NAPA and I really just didn’t have the right parts I needed to do the fuel lines. I did, however, have good luck with fabricating a bracket for the brake fluid reservoirs.

I did do some work with the fuel lines — I started to run the hard lines, but decided I really needed to have the fittings and such that I needed to get the lines run to the tank before I bent and installed all the hard lines. The basic idea is that gas runs through a stock Ford fuel line from the tank to the fuel filter. I need to fabricate a bracket for the fuel filter, as well. From there I need to create a rubber line to go from the filter to the end of the hard line. The hard line then runs to the engine bay, where it will then terminate in an -AN fitting. The engine bay will all be braided stainless lines. The return hardline will then run back to the rear of the car where it’ll probably run through a rubber line as well and into a short adapter line so I can still use the stock Ford return line going to the tank. Its the connectors for those adapter lines that I need to buy.

I also mounted the pedal covers.