Its been two weeks since my last post. During that time I’ve spent quite a bit of time in the garage trying to figure out how I’m going to run heat in the car. The heater unit that Factory Five used to sell isn’t really well designed for the car — it can be installed easily enough, but not attractively. I want to have the entire heating system hidden inside the dash area, not hanging out in the engine bay. I made some progress with it today.

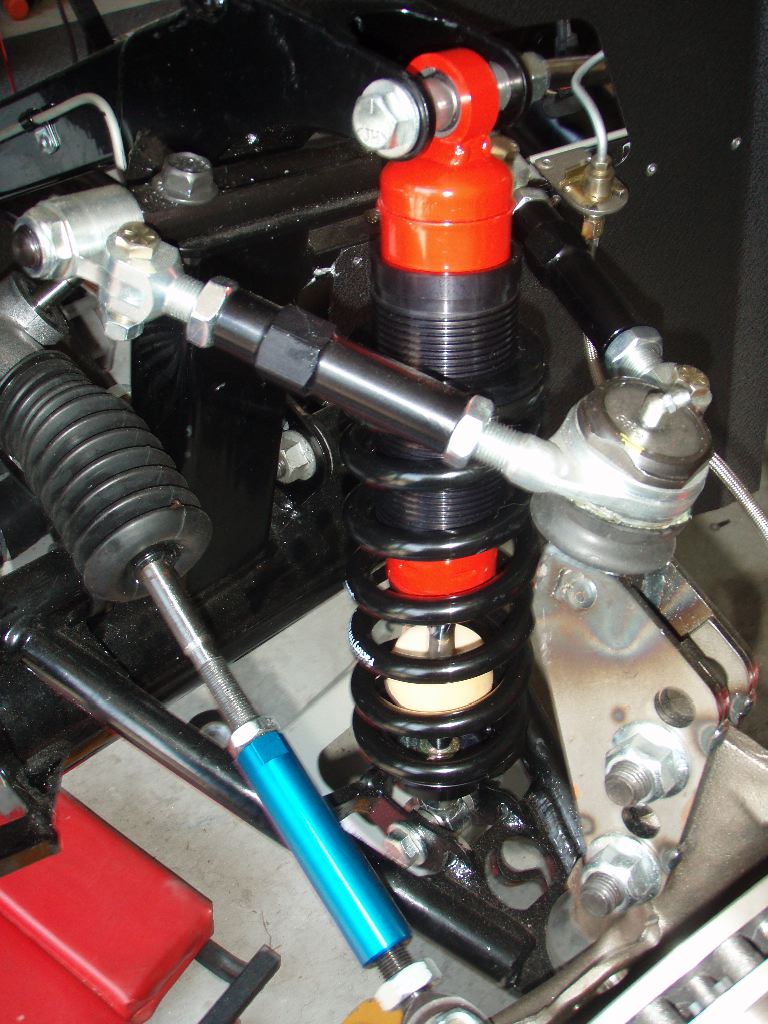

Additionally, I got replacement suspension components for the car and installed those today.

Factory Five has had a “problem” for the last year with reports of shock breakage. While the actual numbers have been very low, and all the data Factory Five has produced suggests its a combination of install error and a bad batch of springs, they’ve stepped up to work with Bilstein to get upgraded shocks onto the car. Along with that process, Koni stepped up and offered their shocks to Factory Five at below cost, presumably to stick it to Bilstein. As a result, Factory Five was selling their Koni setup for half the normal price.

Side by side, its difference is pretty clear. These are the front assemblies. The Koni is a much beefier unit, and the spring rate is somewhat higher. The Bilstein setup had the same spring rate (450 lbs/in) in all four corners. The Koni setup is 500lbs in the front and 750 in the rear.

Swapping the units out only took an hour.

The results:

The front drivers’ side.

The front passenger’s side.

The rear passenger side.

The rear drivers’ side.

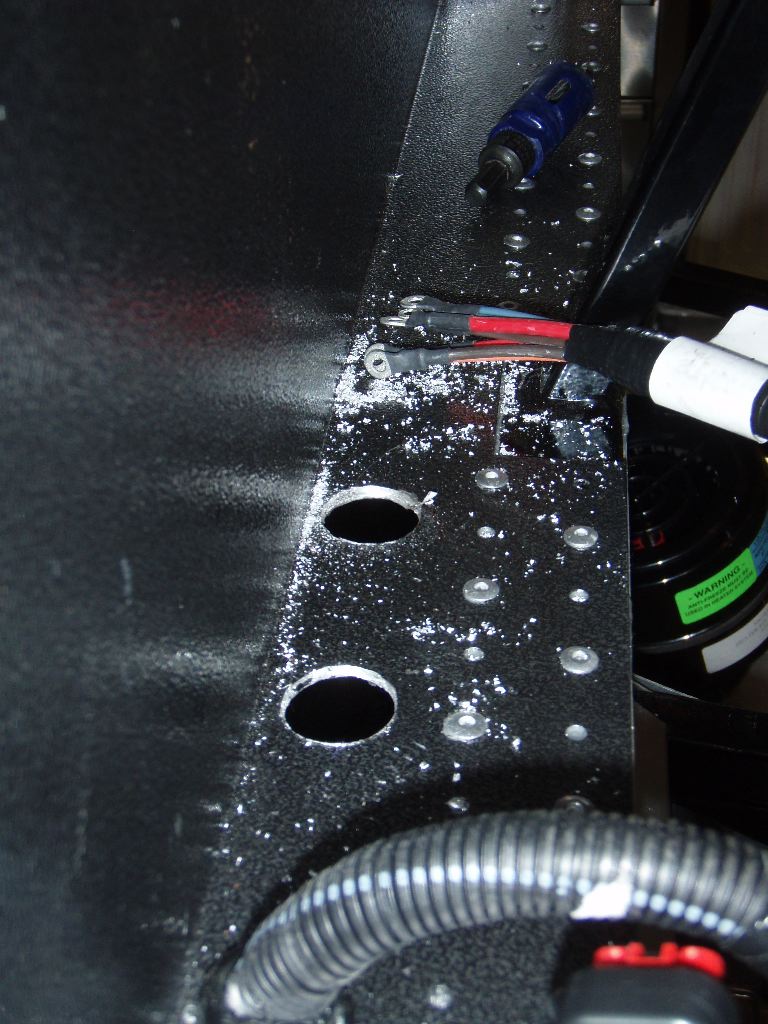

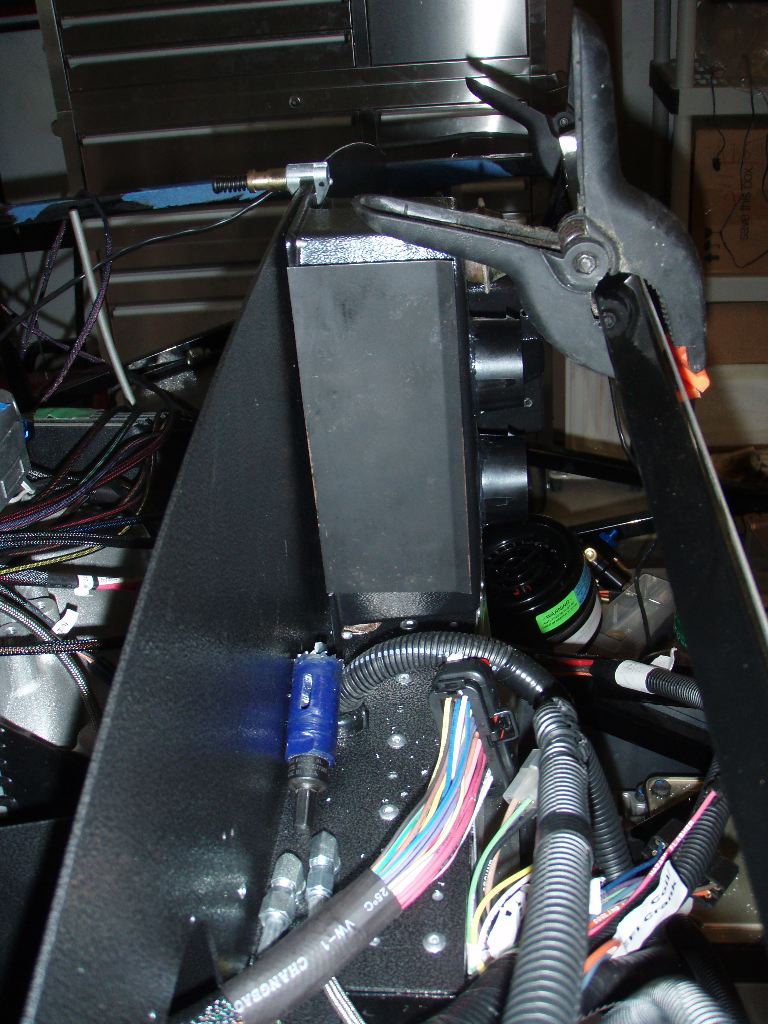

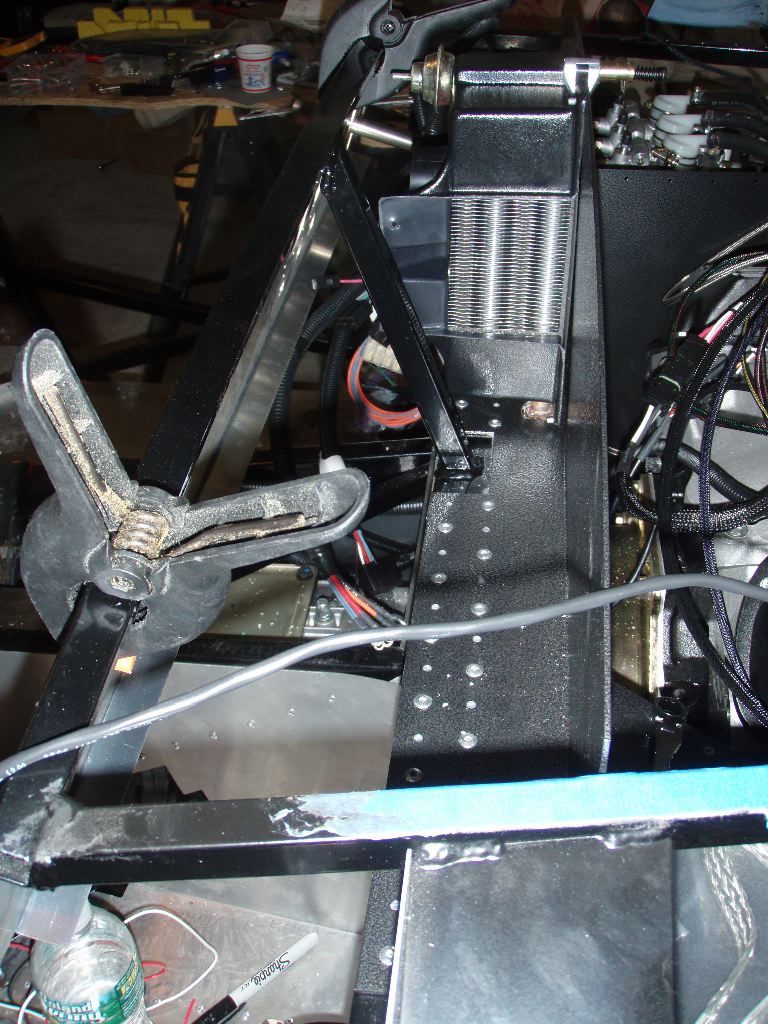

In addition to the suspension, I spent more time working on the heat. In a moment of revelation this week, I realized the hole I had in the firewall, which used to have the alternator wiring, was in a good spot to put the heater core, at an angle I hadn’t previously considered (with the water ports going straight out the bottom of the firewall).

By putting a second hole to the right of the other one, the heater box fits perfectly in the dash — the top edge is right at the top of the firewall, the inlet faces to the right and the outlets are to the left and to the front.

The outlets are barely visible in the engine bay, which will allow me to run the heater lines directly up and under the air cleaner where they won’t be visible.

I also have been constructing a vacuum forming table, which is essentially a table that can draw air from its surface. By heating various kinds of plastic and sealing the soft sheet over a mold, the vacuum will draw the air out and shape the plastic tightly to the mold. Using the table I’ll be able to fabricate both the plenum I need to get air ducted out of the heater box, but also to route air to the heater box.

My current plan is to use an inline 240cfm blower in the fender, routed through soft and hard ducting into the dash and to the heater core. This will leave the entire right side of the dash space empty, so I have the option of putting in a large glovebox or a car PC.

I’ll post pictures of the vacuum table after I finish fabricating it.