I started off this weekend intending to get two solid days of work done. Saturday was Valentines day, and for obvious reasons that was out of the question, but today was Presidents’ Day, so I had Sunday and Monday to work on the car. I ended up doing very little yesterday, but today I made a ton of progress and in-all I’m ending up the weekend very satisfied with the progress I made.

Last week I placed a very large order of Delphi connectors from Mouser. These are the same connectors that are used in the Ron Francis harness and having a big selection of both connectors and terminals would make it a lot easier to move quickly through the wiring, with things better integrated into the Ron Francis wiring as well as having entirely separate parts of the wiring look better integrated. The parts showed up Friday,

For the benefit of anyone who may be interested in what part numbers correspond to various connectors that could be useful when building a Factory Five car, these are the parts I ordered.

I decided to start off by replacing the three separate connectors I had between the power relays and the rest of the car. I wired these up a couple weeks ago. They would work, but the wiring was quite a bit longer than it needed to be and was bunching up behind the dash. I decided to use a 4-position Delphi connector to wire these up.

The male connectors were crimped and soldered into the relay wiring. These then are inserted into the plastic connector itself, and the female connectors were wired up to the chassis harness.

The new connectors definitely look better, and a good eight inches of wire was pulled out of the chassis portion of the harness. (And if you’re wondering, after looking at the parts list above, why I used a 4-position and not one of the 3-position connectors I bought — well… I forgot I had 3-position ones. Oops!)

The next thing I was going to work on was the rest of the headlight and parking light wiring. This was the wiring that made me realize I didn’t have the relays I needed last weekend, as well as lead me to decide to order the Delphi parts. I decided, instead, to work on the wiring for the fuel injection system.

The Powerjection/Boss-EFI system came with its own harness which integrates all the fuel injection parts and engine sensors with the ECU behind the dash. Its a nice, well designed generic harness, however it was not going to integrate into the rest of the wiring as cleanly as I wanted.

The harness has a large bundle of several dozen wires coming out of a large connector. These were bundled together with a large wire loom, which then broke out farther down the harness into all the separate circuits for the car. Unfortunately an assumption was made with it that all of the wiring — engine, fuel system and power, are all going to the same place in the car. I didn’t want to clutter the engine bay running wiring around that could’ve been better run elsewhere, so I started, unfortunately, disassembling the harness. While it was very well made, it was also very easy to take apart. All of the loom was braided mesh held on either end by shrink tubing. Cutting off the shrink tubing was enough to get the various parts out.

The large bit of loom was just discarded. As I started to peel off the single and multiple-wire looms, I saved those for use elsewhere.

The ECU has three power inputs — 12v A and B, and a 12v crank feed. A and B are just straight unswitched power inputs. Its unclear why there are two — the manual indicates only feed A is used or needed. The 12v crank feed has power when the car is on or cranking. All three lines were fused — A and B with 20amp fuses, and the crank feed with a 2 amp fuse. Conveniently, I only needed A and crank and the fuse panel with the headlight fuses had two spots left in it.

To do this, I had to pry back out the 12v feeder side of the fuse block and cut the last position off from it — three fuses have constant power, the other is wired to the coil/crank feed of the Ron Francis harness using 1-position Delphi quick-disconnects. The other side of the fuses are wired into the ECU harness .

In the past I’ve mentioned the issues around powering the fuel pump and the how the fuel lines got run in the car. The Powerjection ECU can control fuel pressure electronically by pulsing the ground line to the fuel pump. This requires two dedicated wires run to the fuel pump, and I’d been planning on pulling the Ron Francis fuel pump wiring out and using the ECU harness to power the pump. I’ve had a lot of mixed messages from various people as to if the ECU can properly control an in-tank pump. I decided to just err on the side of caution and just assume that it won’t work. This meant using the return line I put in last week, plus doing some alternate wiring and installing the fuel pressure regulator.

To power the fuel pump, I basically cut off all but ten inches of the fuel pump wires in the ECU harness. The power side I crimped and soldered a Delphi male terminal on to. I used a small screwdriver to pry the fuel pump power line out of the connector that runs power to the fuel pump, and just plugged the ECU one in. All of the existing Ron Francis wiring going to the rear of the car is used as-is. I put a single position male Delphi connector on the old power feed and left it free in the dash. I can reuse the circuit for something else.

The ground side of the fuel pump wiring just got a bare ring connector to be grounded with the rest of the dash wiring.

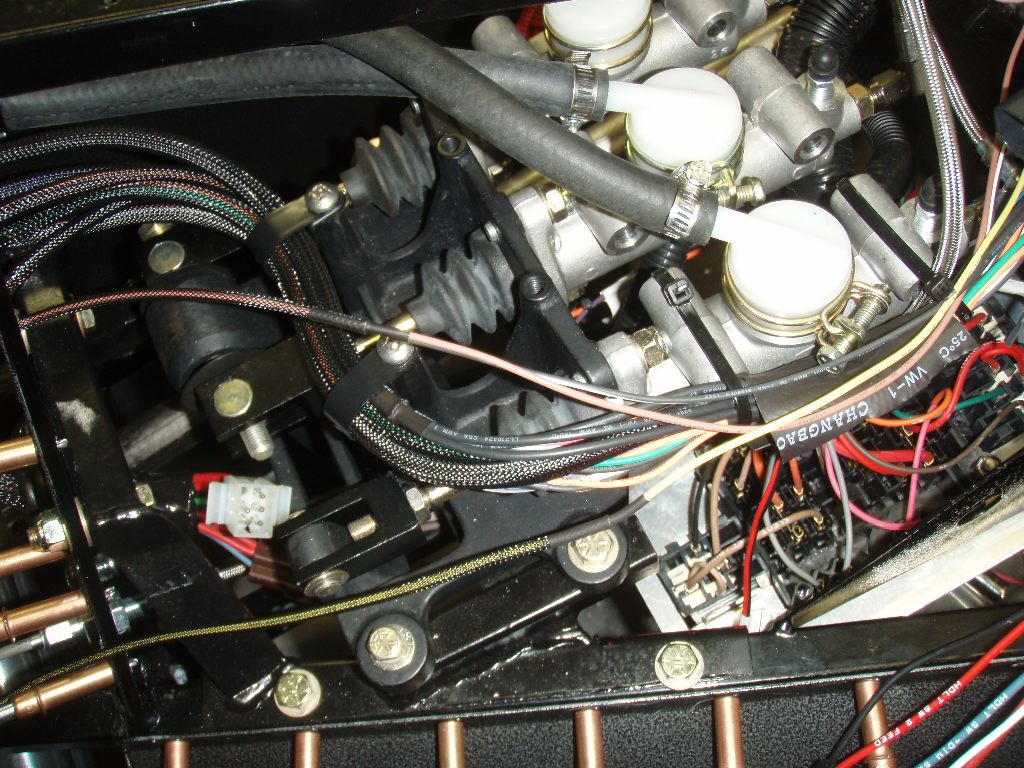

The other necessary change as a result of the decision to do mechanical fuel pressure regulation was to install the fuel pressure regulator. This wasn’t a big deal — I had to modify the mounting bracket to use two bolts instead of one. I also had to make a second -6AN line and a -4AN line for the fuel return. In the photo above, the hard lines can be seen connected into the regulator. I’ll also get an external pressure gauge to make it easier to tune it at some point. I’m not happy with these hoses any more than the last ones, but I’ll keep an eye on them and carefully test them when I first start the car. I don’t think they’ll come apart.

The sensor wires for the ECU I routed through the footbox. Originally I had intended to zip-tie the harness below the pedal frame, but I noticed there were four threaded mounting spots on it, and realized I could use two wire clamps and bolts to route the wiring around the master cylinders, which worked out far better. The sensors are all wired up for the most part. In theory the engine is very close to being able to be started. The fuel lines need to be tested, and the MAP sensor wired up along with the oxygen sensor, but everything else is at least temporarily connected so I could ensure the wires were long enough.

I hope to do the dash wiring next weekend now that I have the majority of the ECU wiring out of the way. There are some little bits of the ECU wiring I’m not clear on — all of the wiring around the distributor and the coil aren’t clear to me. The ECU has two harnesses related to spark — I have to find a better explanation how it all is supposed to work.

In all, I am very happy with the progress I made today. Things are looking better and are really starting to come together.