Yesterday’s time working on the car was, unfortunately, back in an all-too-familiar old pattern of getting very little useful done given the time spent. I had hoped to get the exhaust hangers installed, and get the under-dash panel installed. I ran into issues with both, and in over two hours in the garage, ended up with basically nothing to show for it.

Like many things from Factory Five, the exhaust hanger setup is just poorly designed and questionably engineered. The basic idea is pretty simple — a metal arm is bolted to a flange halfway down the side pipe. The arm goes under the chassis and bolts via a bushing to the 2×2″ steel frame at the front of the cockpit. A rubber hanger holds the weight of the pipe.

The problem is, what the arm does is really serve as an additional engine mount — I discovered when starting the engine over the weekend, the pipes move a LOT, even with poly engine mounts. All of that motion, if stopped by the mounts, goes right back to the mounting bolts in the headers or the aluminum heads. There’s a known issue with them breaking, which is a good sign that they aren’t allowing enough movement.

In either case, to get a look at the setup and brainstorm ideas, I needed to get the car jacked up. I’ve discovered that it really is not easy to jack the car up anymore. Jack the front up, the rear is too low to get a jack under. Jack the rear up, and the front is too low. I just jacked up the rear, which gave me enough room to get under and look at how the mounts would work.

The rubber Ford exhaust hanger bushing I bought needed to be cut in half, as it was almost two inches thick. Using a hacksaw I cut it in half and then cleaned the two pieces up with a razor blade.

I didn’t get any photos of the exhaust hangers beyond there since I ddn’t get anything actually installed. There are a few options I can consider — make do with these, and hope it doesn’t turn into any sort of an issue. There are some much better designed options from some vendors, but I can’t really justify $60 to solve this problem. I can also just leave them off. Right now I guess I’m leaning towards mounting the bushings and leaving the arms off for now, but I can add them easily enough later.

When I decided to stop working on the hangers and sleep on it, I started looking at the Mike Everson under-dash panel I bought. It would be a clean install if I didn’t have the FFMetal firewall — but both mount to the steel frame in the front of the cockpit. I’m not sure how I want to mount it at this point. I’ll post photos of it once I figure out how I’m going to get it mounted.

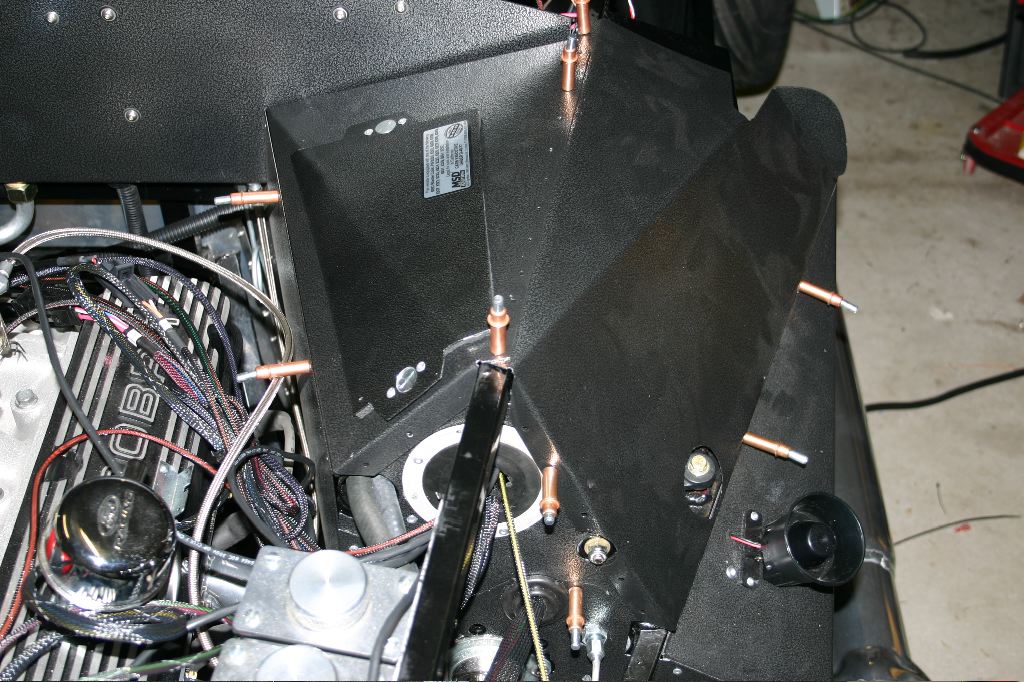

Since that was out, I also looked at the sheetmetal at the top of the driver’s footbox.

Ages ago I had cut out an access panel in the top of the footbox, but hadn’t totally worked out how I was going to get the lid secured on it and sealed to avoid drafts.

Originally I had the twist-lock mounts mounted using JBWeld to the upper side of the access panel, which allowed it to sit flush, although not well sealed, against the lid. The stress was too much on them, though, and they broke off twice. Rivets were a concern because they kept the lid from fitting flush. I decided to drill and rivet the mounts from below anyway, and I basically crushed them as flat as I could using my bench vice.

To seal the box, I used some of the closed cell foam tape around the edge, which both seals the top and raised it up enough to clear the rivets.

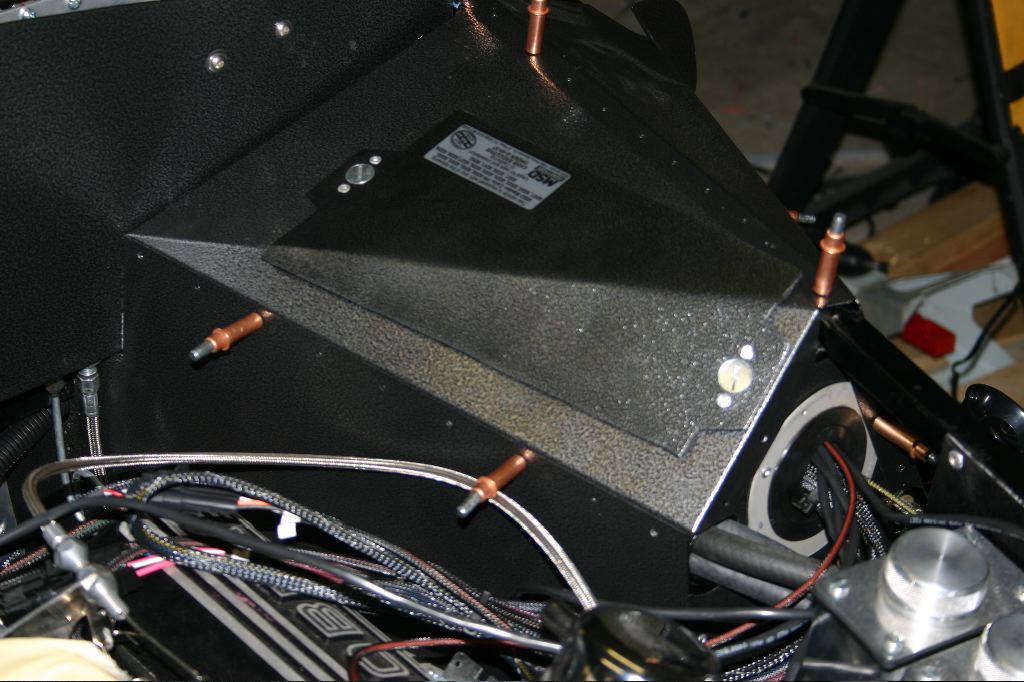

Using some cleckos, I mounted the panels into the car. I’m 99% sure I’m ready to mount these, but it was getting late last night and I was hungry so I wrapped up the work. I’ll probably rivet them after work today.

And, those of you who are being over-observant and asking yourself “Why is that MSD sticker upside down on the footbox lid?” — I will answer your question with the claim that I meant to do that because you can read it from outside the engine bay. Yup. Thats why I did it. I certainly didn’t mix up which side was up when I put it on.