It was another rainy day in New Hampshire, but I got another two hours or so of work done on the car. I had been debating just doing the exhaust hangers tonight for most of the day, but decided that I would wait and do that next week or the following one once the body is on the car. If the side pipes don’t align correctly, I don’t want to have drilled the mounting holes and have to move the mounts because I had to adjust the engine position.

I spent bit of time looking at heater/vent duct routing — I got in some ABS ducting parts today and need to work out where things were going to run. I have a plan at this point for how I’m going to route it, but I need to get a few additional bits and pieces. I think I’ll do that on Saturday.

Instead I decided to focus on the transmission tunnel.

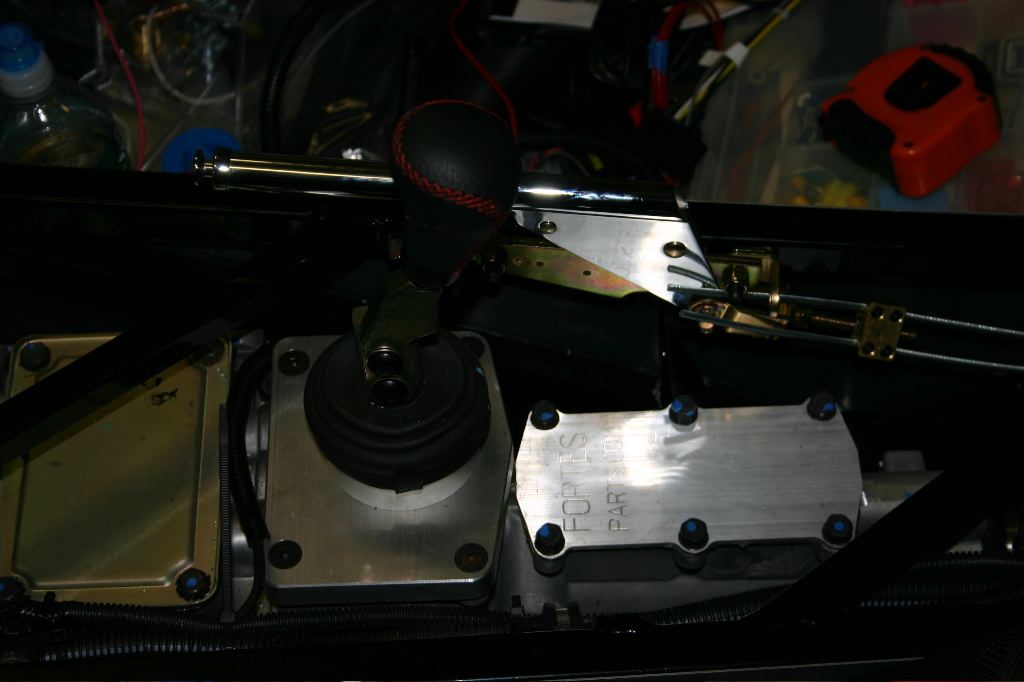

The tunnel is normally covered by a panel with an opening for the shifter.

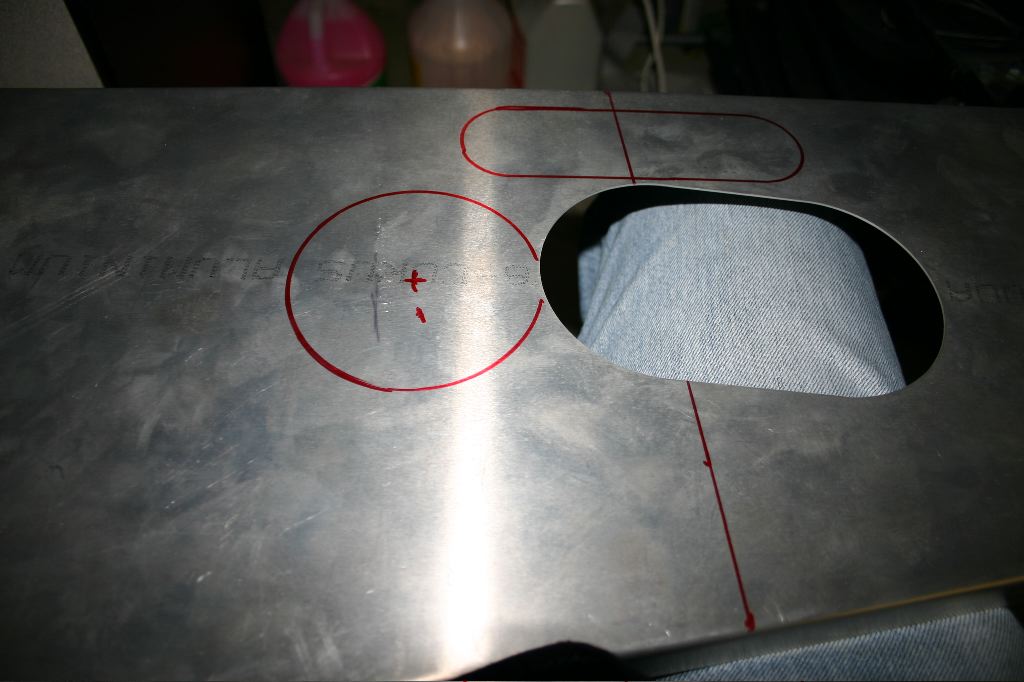

The opening is fairly large to allow for differences in the position of the transmission tunnel. They provide a patch panel with a 4″ round hole in it that they intend the builder to align with the transmission and reduce the size of the large oval. Unfortunately, my shifter is a good five or six inches forward of where it normally is. I started off planning how to make the panel work by tracing where both the shifter opening and the emergency brake opening is.

Factory Five does provide a solid panel to close it off entirely, presumably for people who don’t have a transmission. Well, not really. It somewhat surprises me they included it, but I assume its for people who run a midshifter or perhaps automatic transmissions. The patch panel, because of how close everything was, overlapped the places I needed to cut openings.

I started off by cutting the large opening for the shifter with the jigsaw. The e-brake opening was giving me grief with the jigsaw so I ended up cutting it very slowly using a cutting disc on my Dremel.

I then caulked and riveted the patch panel on, and tool the dremel and cut out the notches in the patch panel where it extended into the openings.

There was a problem, however. Normally I would assume you could fit the panel over the emergency brake handle by lifting it up, but the brake cables are really tight and I can only lift it two or three clicks. I could probably rig something to get it on by removing the shifter, but I really want my transmission tunnel top to be removable when the car is done.

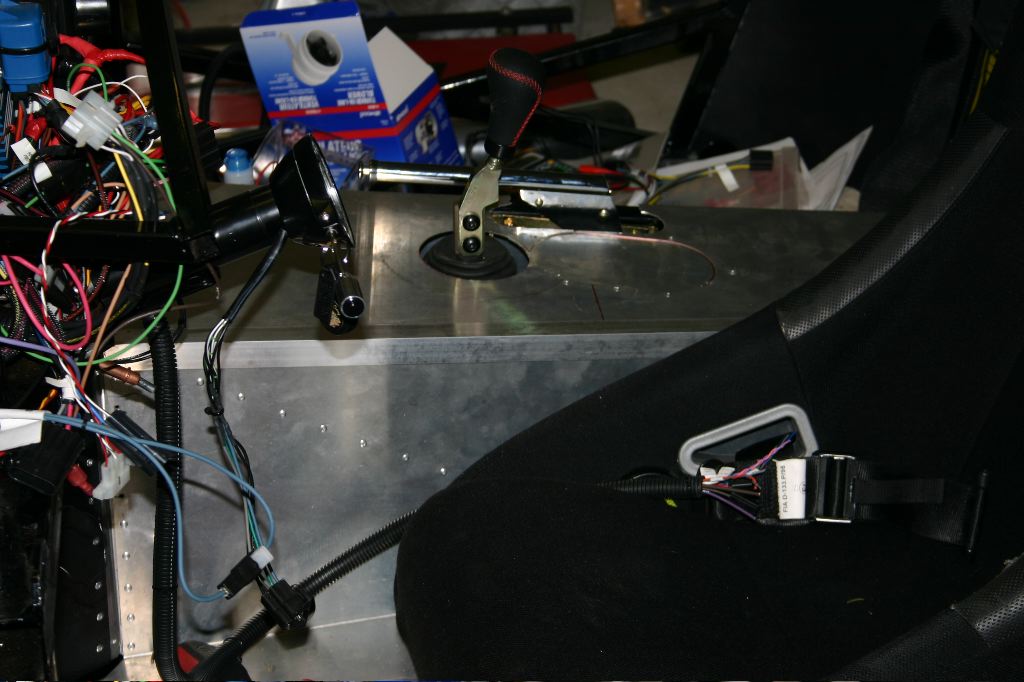

After some time thinking about it, I decided to just cut out the side of the e-brake opening. While I was at it, I cut the passenger side flange off the panel. With the flange gone and the slot cut, I can just slide the cover into place.

Even without taking the shift knob off, the panel fits now.

While I was at it, I also cut off the driver’s side flange leaving the top just a flat panel.

Of course, this means I don’t have the flanges to rivet to the car anymore. It turns out I was planning on cutting them off anyway, not for functional reasons, but for aesthetic reasons in the car.

One of the details on the interior I’ve been planning for the last year or so is the use of blocky, heavy duty polished aluminum trim as accents. The switch panel on the dash is a good example of that overall look. To tie that look from the dash to the rest of the cockpit, I intended to run 1″x1/8″ aluminum L-stock along the top edges of the transmission.

To hold them on, as well as to hold down the transmission tunnel, they will be bolted to the transmission framework using polished button head bolts, screwed into aluminum rivet-nuts in the 1″ steel tubes. These will fit in with the overall look on the transmission tunnel, which will be covered in black vinyl and padding like the dash and have two spun aluminum cup holders as well as a switch panel like the one on the dash with the heat and seat heater controls. This one will likely run lengthwise on the drivers side of the tunnel, but I haven’t fabricated it yet.

This weekend I’ll use the drill press to drill the holes in the trim pieces, then drill through those holes to position where I need to install the rivnuts.

Tomorrow night the plan is to work on the engine tune again, as the rain should’ve broken by then.