As I sat down to write a post for this site today, which I haven’t done in a few weeks, I realized that it’s now been over three years that I’ve been working on this car. Thinking back over the other events in my life that have happened during that time, its just drives home how long of a period of time that really is. In a few months I’m going to be driving the car for the first time down to my fourth Open House at Factory Five.

And, of course, its still not done. At least its legal and drivable now. The last few weeks have been more about driving the car than about working on the car. With the unusually nice streak of weather in mid-March, I decided to permanently take the Miata out of the garage for the season, and get the Cobra set up to be able to drive. After getting it moved, and off the wheel dollies, I looked it over and took it for a couple drives. I’m up to about 90 miles on it now!

The weather has shifted back to more seasonable coolness, and the rain seems to be never-ending, so I decided to take advantage of a period of a couple weeks of both lots of predicted rain and other plans and take the interior of the car back apart to take care of some loose ends.

The drives I have done this spring reminded me of a few things I really needed to deal with — primarily the oil leak on the engine, which really makes a HUGE mess of the car, including in the passenger footwell because of an opening in the sheetmetal almost in line with the bellhousing, and the loose steering column and some slop in the steering.

Originally I had intended to drill a tap hole and bolt the upper and lower halves of the steering column together so it would stay in place. The problem I have driving is if the column moves in too far towards the dash, the friction from it hitting the turn signal housing causes the turn signals to come on when I’m turning the wheel (i.e., going around curves, not actually making a left or right turn where I’d want the turn signals).

I did some research online and it turns out that while some people do bolt them, there was two parts I had left out that were likely causing the problem. There were two Belleville springs (which are basically slightly cone-shaped washers) that were supposed to be in the two circular indentations on the steering column. They provide the pressure that is supposed to make the two parts not slide freely.

Needless to say I don’t have them in the car, nor do I seem to have them at all. I don’t recall ever seeing them, and my steering hardware was all stored together, so I’m guessing I may not have gotten them at all. I ordered a bag of them from McMaster and can try re-assembling it later this week. I’m not convinced it’ll solve the problem, but its a reasonable first start. I may drill a hole in the lower part of the column this week and tap it for a set screw, just in case. Worst case I won’t need to use the set screw. The two pieces are meant to slide with some pressure so the column can collapse in an accident, but given the angle its at going to the rack, the U-joints would take the impact, not the column, anyway.

The loose steering turned out to be the lower U-joint being loose on the steering column. I’m positive I had this tightened down, but the steering has been sloppy since my first drive. I don’t know if it worked loose or not, but I tightened it back down. If it comes loose again, I’ll look at using some threadlock to make sure it doesn’t back out. Because the steering wheel isn’t in the car, I can’t verify that this was the cause of the “dead spot” in the steering, but I’m 99% sure it was. It was very loose. That’d be an “oh sh*!” issue if it wasn’t for the fact that with the angles on the U-joints, there’s no way the shaft could’ve come loose driving. There’s not enough slack in the column for the fitting to come off the rack.

While taking apart the steering, I also decided to pull the dash out. It turns out the Velcro really holds well — it was *hard* to get out. I needed to do a few things behind the dash, though, so it was good to get out. First off I had to remove the 12v outlet under the dash in the underdash panel — it was going to be in the way of the passenger side center console panel.

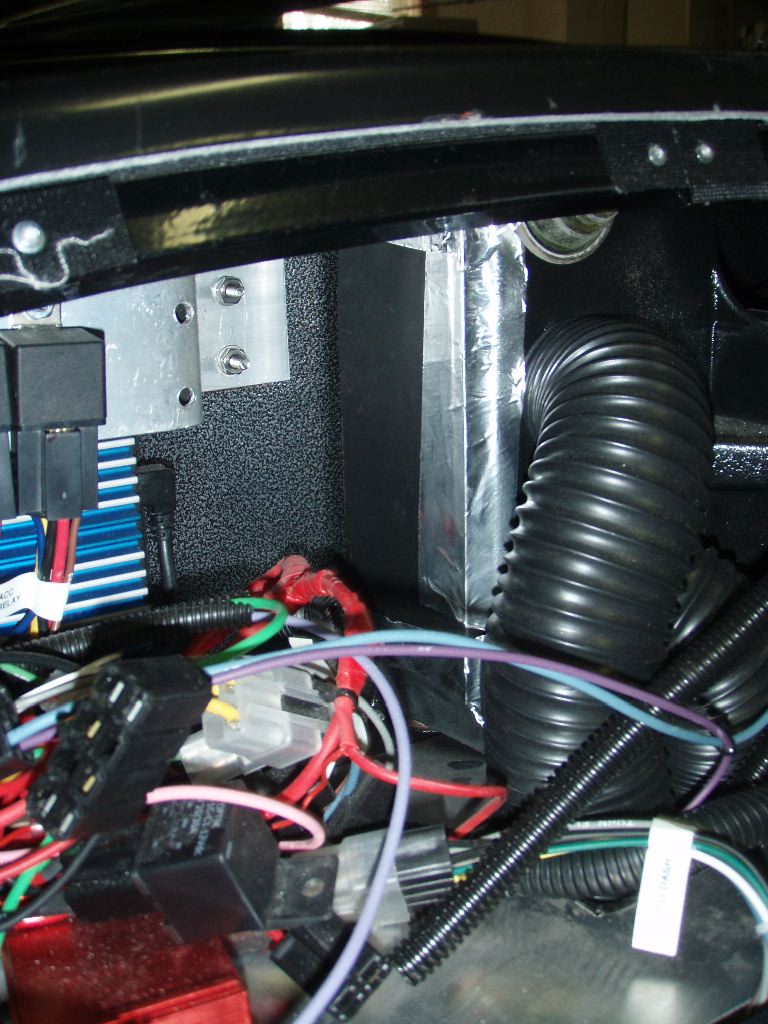

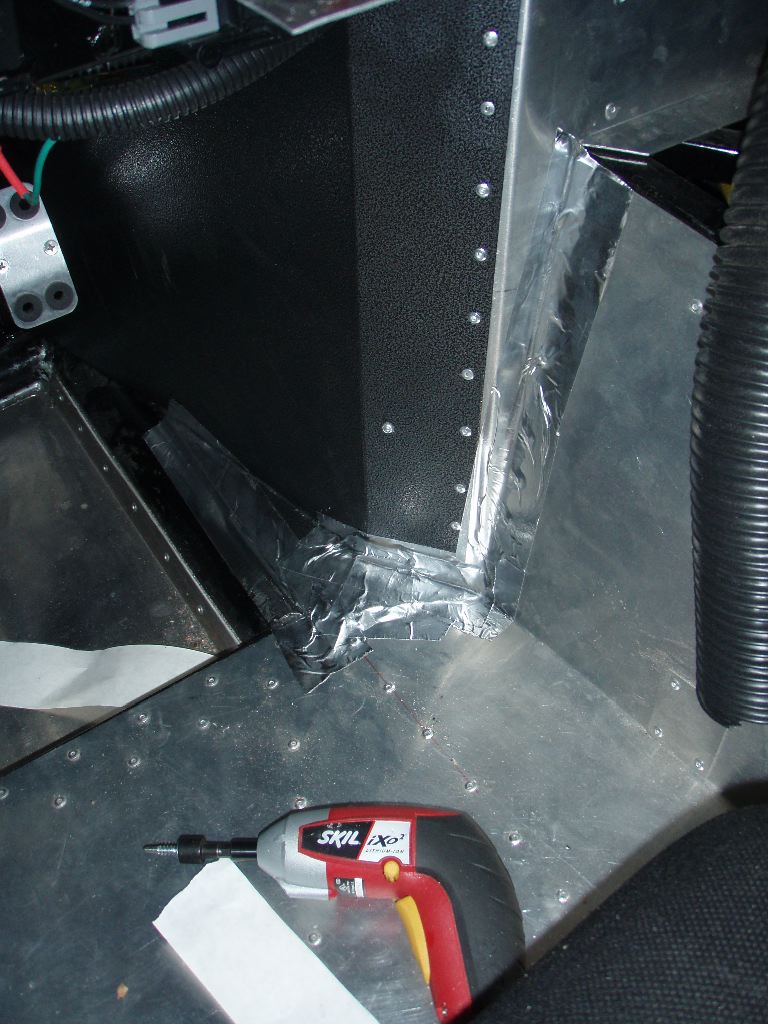

The other thing I needed to do was seal off the bottom opening in the heater core. I had forgotten to do this before re-assembling the dash last year, and it meant both the heat and vent weren’t going to work properly. I used aluminum duct tape to seal it off, and I’m confident it’ll hold. (If I’d thought of it before the core was installed, I would’ve sealed it with epoxy like I did with the inlet side, but there was no way to do it with the core in the car…)

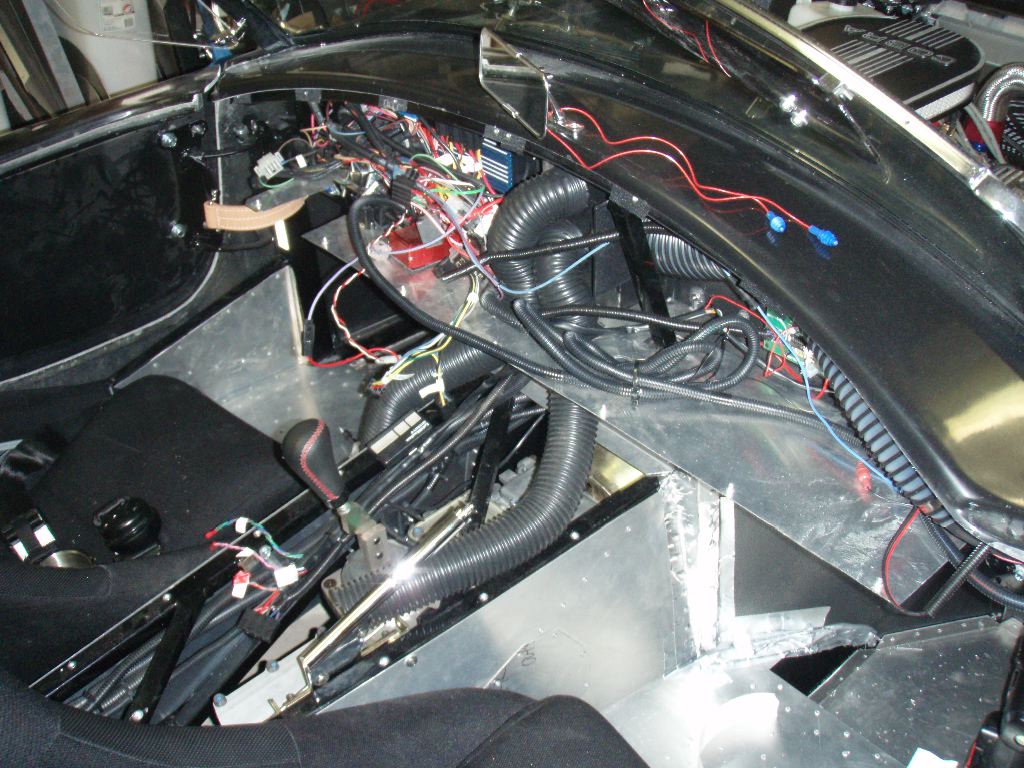

I also did a bunch of cleanup work on the aluminum in the car, and used both caulk and the aluminum tape to seal some of the joints in the panels. The passenger side (on the top photo) was particularly a problem because of the oil that was spraying through the gaps here. It turned out the whole edge of the panel hadn’t been riveted. After cleaning everything with degreaser and acetone, I drilled and riveted them, then sealed the footbox gaps and taped everything up. The drivers side had no openings, but I taped the edges anyway. I may start putting the carpet in the car this week, and I think I’ll seal all the edges this way to be safe.

Last week I actually got the vinyl covering installed on the passenger side center console panel. This morning I took care of the driver’s side as well.

The process basically amounted to using some fabric glue and spray adhesive to get the vinyl pulled taught on the wood, and then using a ton of staples to attach it. Once the vinyl was installed, I could cut small holes where the bolts went, and mount the side aluminum.

Having all the parts of the interior out of the car made for a unique opportunity to see them all close together. The polished-aluminum and exposed hardware theme is working out nicely, I think. I had to get a couple other parts from McMaster so I could finish the transmission tunnel top and get heat/cool vents on the side of the console, so I can’t do anything more at this point with these.

This week I’m going to pull the seats out and look at what would be involved installing the carpet. I had planned to do this after painting, but I think at this point I have to be realistic that I can’t paint it before next fall — if I tried, I’ll likely just miss the Open House or later summer driving.

I do want to get in touch with Mike Forte about the oil leak — he’s been offering to fix it for over a year now and with the car legal I can get it down to his shop. I had wanted to swap the oil pan in a hope that the leak is from the oil pan seal, but the more I look at where the oil is, the less I think its possible that its just the oil pan. I’m still not losing an appreciable amount of oil — definitely less than a quarter quart in two years of the engine sitting and leaking and almost a hundred miles of driving. Still, its a giant mess and needs to get fixed.