At the end of my last post I said I hoped to get time yesterday to get more work done on the car. Amazingly enough, I actually did. I spent another three or four hours working on the car. I focused primarily on getting the hydraulic lines for the brakes and cutch filled and bled, although I did get a few other little things done.

Saturday night I went up to Electronics Surplus Services in Manchester, NH. I had bought the aluminum handles used for the dash switch panels there and needed to buy another four or so. Unfortunately, being a surplus store, they didn’t have them anymore. I’m not sure what I’m going to do about the two other switch panels I wanted to make. They do have good prices on clamps, though, so I bought some that I needed for the wiring.

As part of getting temporarily installed bits of the car into their final places, the three wiring bundles that were run through the transmission needed to be mounted. I used four inch and a half rubber coated clamps.

They are tucked up high in the drivers side of the tunnel. In some rear end configurations this might not be such a good idea, but none of the parts move relative to each other with the IRS, so short of the drive shaft breaking, nothing can hit these.

The bundle then shoots up and over the IRS cage to run immediately below the trunk floor.

The bundle attaches to the upper bar of the IRS cage with a zip-tie. There isn’t really clearance enough for a clamp here, and its not really holding them as much as preventing them from sliding around. They won’t go anywhere.

I also disassembled part of the rear harness. The wiring bundle to the fuel pump and fuel level sender was very tight around the trunk boxes. I didn’t want that to become an issue, so I just added about six inches to the loom on the fuel pressure sender (the smaller loom in the photo above) which gave me more then enough clearance to fit them around stuff in the back of the car.

In hind sight, things like the wiring should be done first in the car. If I ever did this again, its vastly harder to get clamps screwed or riveted in for all the wiring, brake lines and fuel lines with the engine, transmission and rear end in the car.

The next thing I decided to work on was filling the brake fluid reservoirs for the brakes and clutch and bleeding the circuits. Generally this shouldn’t be too hard, although brake bleeding is one of the things on a car that I just really hate doing because its just a pain in the rear.

In the past I used a Motive Power Bleeder on my two Audi S4’s. This is a great setup — extra fluid is put into a jug which is screwed onto the car’s reservoir and the whole system is pumped up to 15-20psi. The pressure forces fluid through the system so all you need to do is crack the bleeder screws and let the fluid flow until the air is out.

Unfortunately I don’t have a fitting for the Motive bleeder to fit the CNC reservoirs so I had to do it the old fashioned way. I spent the better part of three hours doing this — both futzing with a hand pump to draw fluid to the ends of the circuits and doing the traditional pushing of the pedals.

The basic process was to bleed the master cylinder, then the longer of the circuits off it, then the shorter one and repeat until things worked. This was made vastly more complicated because of the way the Wilwood brakes work — a crossbar regulates pressure from the pedal to the masters, so once you get some fluid in, say, the front the pressure from the pedal just goes to the rear. What that effectively meant was I had to half do the front, then half do the rear, then repeat.

On top of that complexity, I discovered a lot of leaks. Pumping the pedal would cause puddles of brake fluid on the floor, but the hand bleeder would just suck air into the system. It took a while to realize I couldn’t get fluid flow because of air leaks in the circuits. I worked my way around the car tightening things up and eventually got the brakes mostly bled. I’ll have to do it again at some point when the air bubbles work their way out of the fluid, but the brakes do work now.

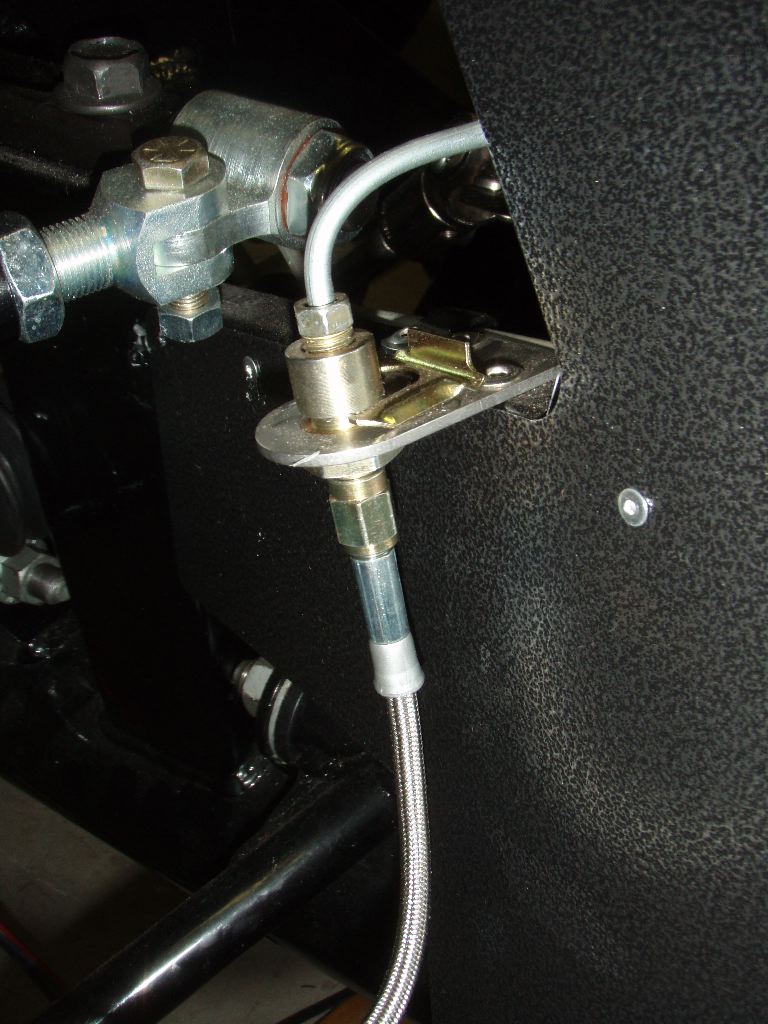

These are the fittings I had leaks in:

This fitting in the T-fitting in the rear brake circuit. The line that ran to the passenger side caliper leaked like crazy. I couldn’t get it tightened enough to stop and was getting ready to replace the line. I unscrewed it entirely and cleaned out the contact surface on the line and tightened it back up and it seems to not be leaking. I’ll have to watch it a bit.

The driver’s side front brake line was leaking, but I think I just hadn’t really tightened it. I installed all this stuff over a year ago, and needed to make a pass through everything to tighten them down anyway.

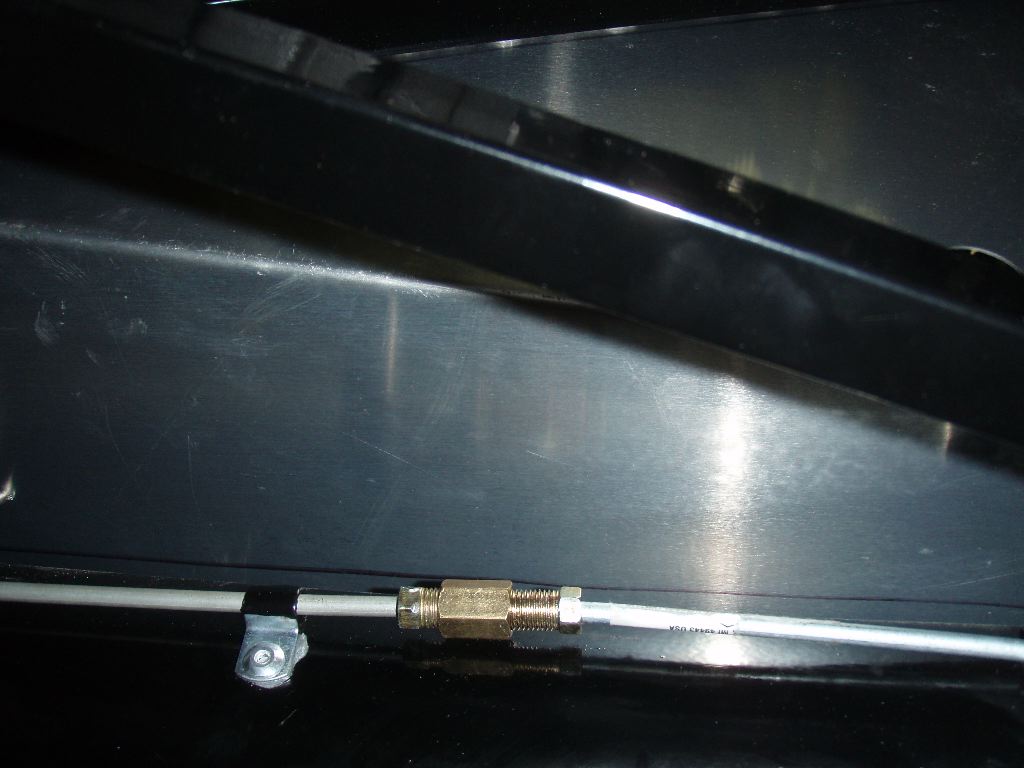

The coupler on the rear brake line under the driver’s floor was also slightly leaking, although it was a small leak and didn’t start until the brakes were working and I could put real pressure on the pedal.

I also bled and filled the clutch line. This one definitely needs to be bled again, but because of where the bleeder is on the slave cylinder, I couldn’t do it by myself. The clutch does work though:

[youtube:http://www.youtube.com/watch?v=y6Z44dzSfB0]

I think the next step is going to be to finish mounting the fuel lines going to the front of the car, and getting the transmission filled. The rear end suspension control arms aren’t torqued down, nor is the tie rods or the steering rack in the front. I need to do that as well, but need to do at least a partial alignment before then.

I still think it looks very positive for starting the car in April. It should be drivable as soon as its startable, as well.