This has been a disappointingly slow week where work on the Cobra has been concerned. While I’ve gotten a few things done, I’ve gotten more stuff started, or screwed around with, than I’ve actually finished. Generally speaking, if I want the car registered by the end of May, I can’t have weeks like this.

Part of the problem stemmed from the realization that I couldn’t reach the places where the wiring goes for the various lights on the body while the body was on the car. I can’t finish the lighting until I take the body back off, which means finding someone to help me do that.

I’ve also been dealing with the fact that Factory Five appears to have just randomly drilled the holes for the lights without using any templates or verifying anything — they’re all wrong and its meaned cutting larger or extra holes in the body. I’m not sure why that surprises me, given all the other problems with the body and kit, but its annoying. I payed extra for the cutouts and I’m going to have to pay now to fix the extra holes in the body because they did it poorly.

I had another issue come up this week, as well. The control module for the Digital Guard Dawg system seems to have partially failed. The unit works for turning on power to the car and starting the motor, but the wiring that controlled the lighting of the start button has failed. I have to ship the controller back to them, which means I can’t even turn the car on until I get it back. This may be the thing that keeps me from finishing the car this month.

I have gotten a few things done — some I remembered to get pictures of, some I haven’t.

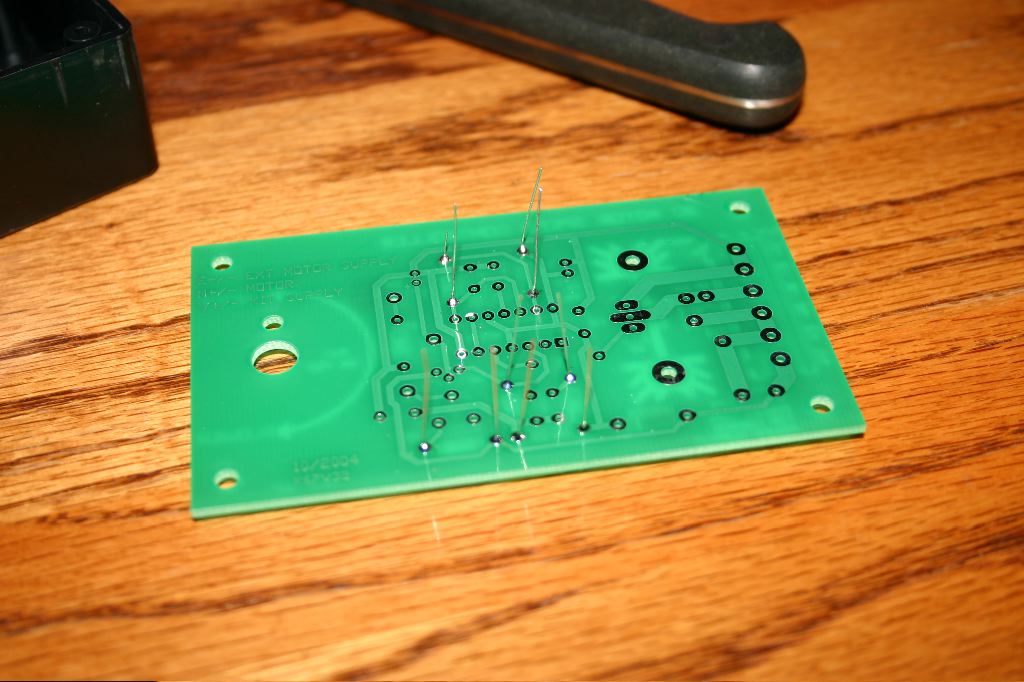

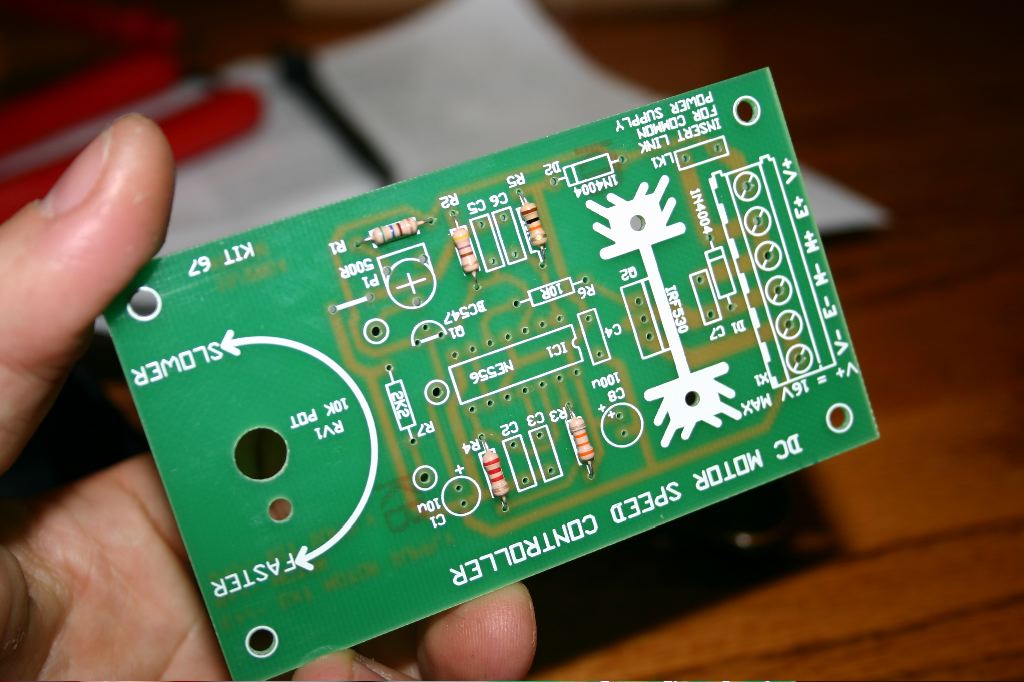

Earlier this week I started assembling the fan speed controller. It wasn’t too bad, just a couple dozen parts to solder onto the board. It was busy work, but relaxing.

Basically, I just soldered on all the parts, starting with the smallest ones so they wouldn’t fall out when I flipped it over.

The finished unit appears to work correctly. The potentiometer which controls fan speed will go into a switch panel on the transmission tunnel, but I need to get some wire to run to it and come up with how I want that panel to look.

I got the passenger seat bolted into the car, to ensure everything fit. Part of doing that, I also spent an hour double checking that I couldn’t possibly fit my Recaro seats in the car. The Recaro seats are vastly better, but the bases of them are just too wide. I actually think I probably could fit them with a couple changes to the frame (moving the belt mounts apart, mostly), but its too late for that.

I moved the coil from the top of the engine to the front of the engine. Fortes had the coil on the top, and it turns out from reading some stuff online, you can’t mount them horizontally, so I moved it. I’m not sure why they put it there.

I discovered the coolant hose from the recovery tank is also leaking, but haven’t tracked down why. Hopefully its a leak at the hose, not a leak in the tank. Its just water right now, though, so it didn’t make that much of a mess.

Last night I started working on the transmission tunnel cover. The basic idea is that an aluminum trim piece covers the transmission tunnel cover, and wraps over the edge of the carpet.

I took a piece of carpet to get the spacing correctly, then drilled holes in the transmission tunnel frame to put rivnuts in, so I could bolt and unbolt the cover.

The passenger side is basically done, although I have to “massage’ some of the bolt holes as they’re a little off, and today I’ll do the driver’s side.

Thats about it for the week. I think today I’m going to focus on the hood hinges and latches, as well as the trunk latches and lights, as I can reach those. Hopefully tomorrow I can get some help and get the body back off the car and I’ll do the rest of the light wiring on the buck.

I think I can wrap up most of the chassis work in a week’s worth of evenings, so I may be able to get the body back on the car next weekend, if I get lucky. Hopefully the turn around for the push button controller isn’t too long.