Today was definitely a car day — I started off going up to Pat McMahon’s shop where we had a mid-winter “Cobra” get-together (although it was too cold for anyone to actually drive their car there). Coffee, donuts, good conversation and free parts. You can’t go wrong with that. I actually came back with a few items I will find useful — a bus bar I can use for a better set of grounds behind the dash, some battery cable boots (which I needed, as I had none on my battery or alternator lines), and best yet another set of the decals I had bought to use as icons for my dash and console switches. I needed an extra set, but balked at paying another $20 for the one extra sticker I needed.

After returning home, I got to work on the car — I was planning on playing with some emergency brake arrangements, and starting to build the center console.

As it turns out, like usual, I didn’t make the progress I’d hoped, although I spent a solid four hours working in the garage.

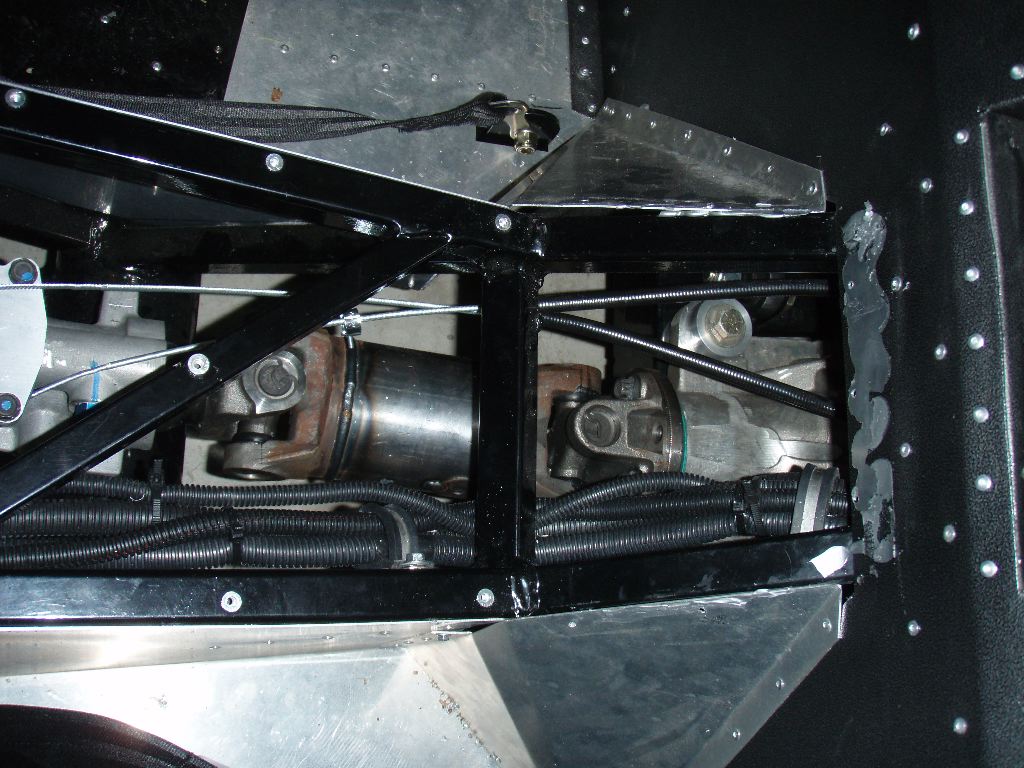

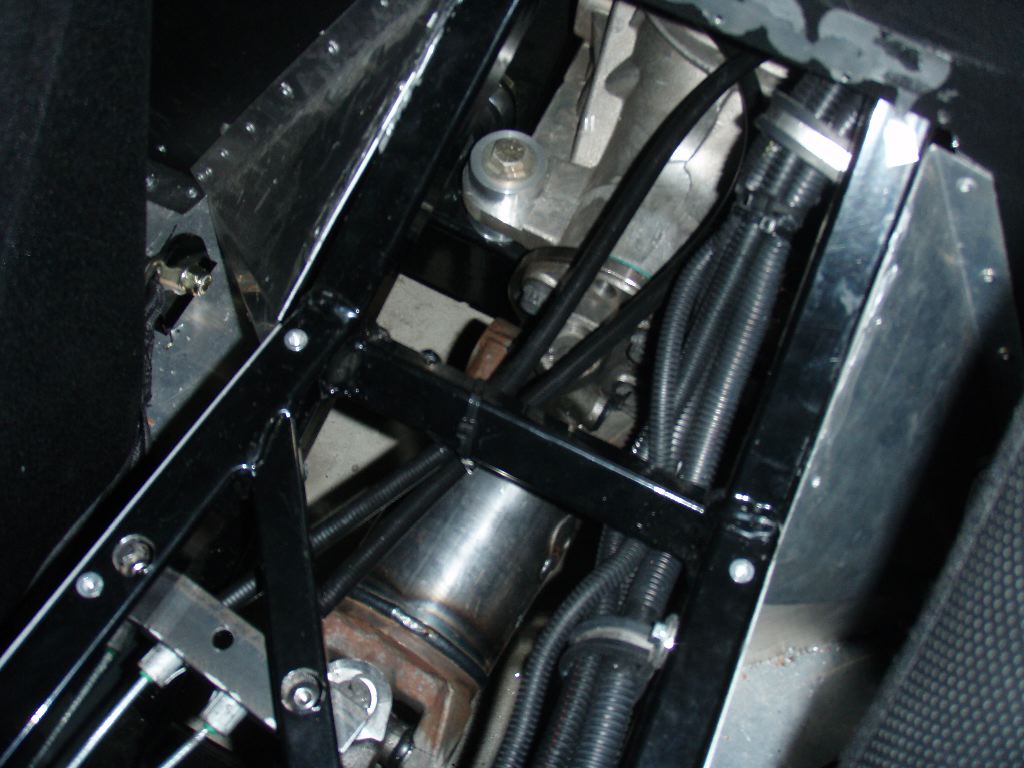

At least half that time I spent mostly staring at the transmission tunnel and trying to visualize various configurations of parts that I could get in without removing the transmission or emergency brake, and without losing future access to the transmission tunnel. I also played with mocking up three or four arrangements of mechanisms for the emergency brake, both where it was and moving it to the left side of the driver’s seat.

I tried in vain to remove the emergency brake cables, but because of the way the clips were holding them in place, I just couldn’t get them out without being able to grab the cable itself from behind so I could apply pressure to the clips. To do that, I had to remove one of the riveted and siliconed panels — the rear of the transmission tunnel. Drilling out the rivets also required removing the seats.

It turns out the silicone really grips tightly — it tore the powdercoating off the rear of the cockpit. Thankfully it didn’t peel beyond the point that it had been adhered, so it will be invisible when I re-attach it. I may do so using screws and rivnuts, as it turns out its a handy panel to be able to remove.

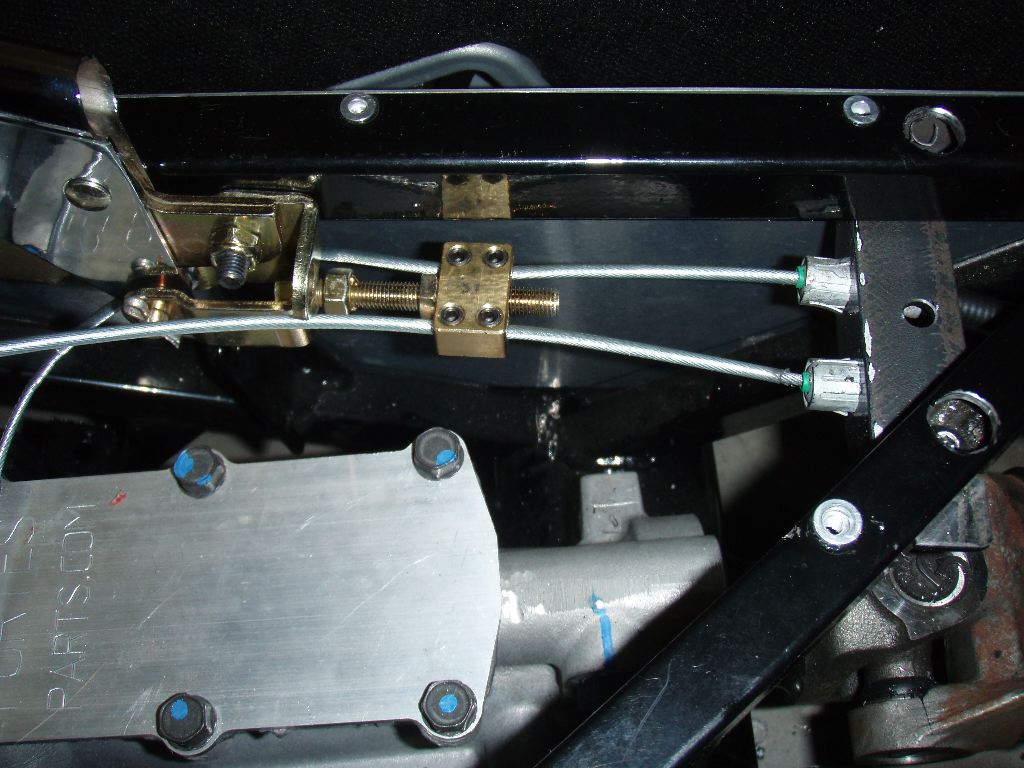

With the cables detached from the mount, I could get a better sense of how much play I had in them. I had been thinking of a couple options — either rigging a lever setup where I could pull the two cables using a third cable, which would run behind the driver’s seat to the e-brake handle, moved to the left of the seat, just below the door, or some sort of a lever setup giving a bit more leverage with the handle where it was. It turns out both were really more complicated than I could reasonably do with the tools on hand — I really needed to be able to cut and weld an assembly to act as a pivot and lever as well as weld in a different crossmember in the transmission tunnel to support it.

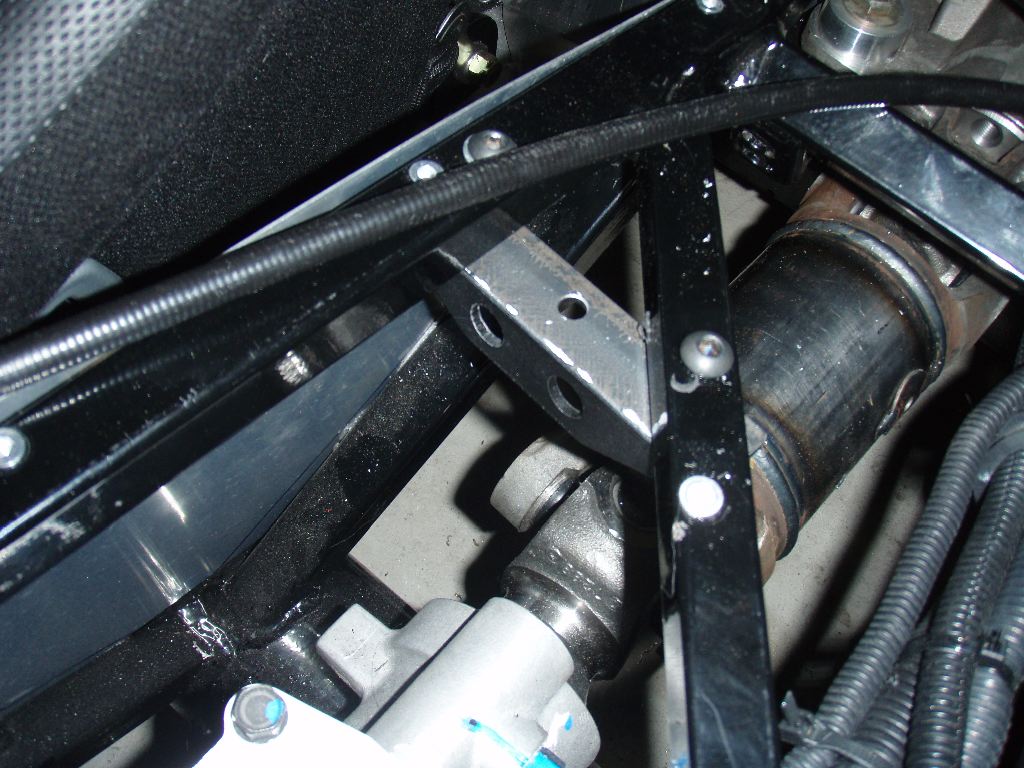

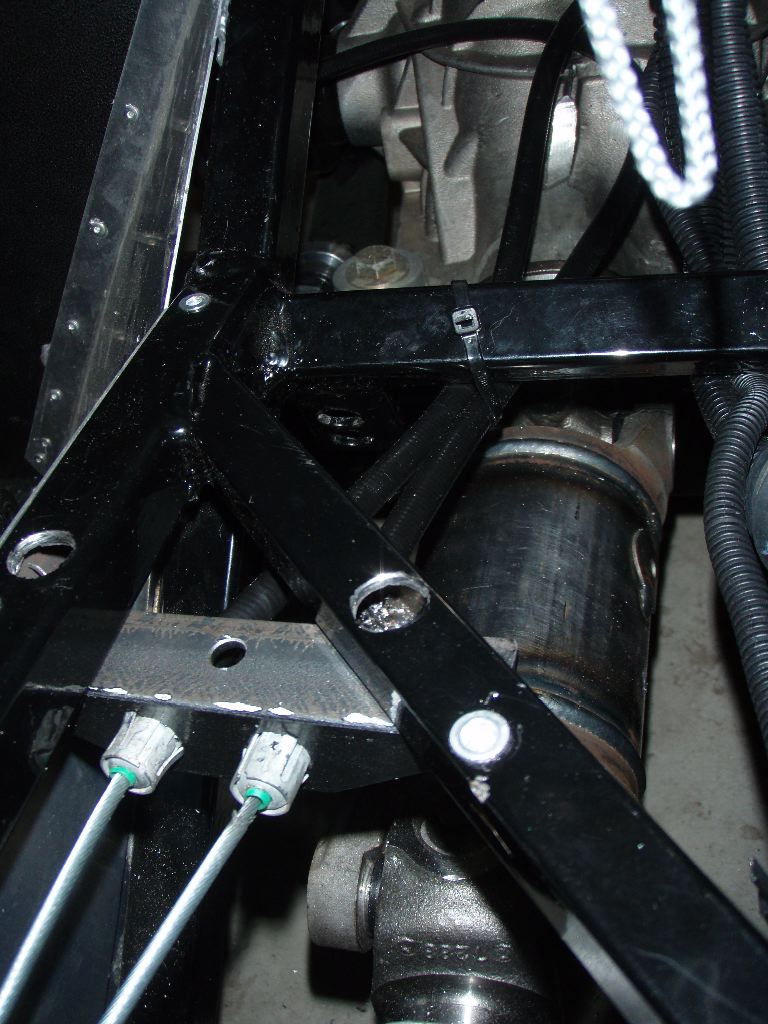

After a good bit of futzing around, I realized the best option I had that would not involve going out and buying a welder was to bolt a different cable bracket at the top of the tunnel and use the rest of the brake mechanism as-is. This got rid of the awkward angle on the cables, and I figured would help lessen the effort to engage the brakes. I started off drilling a couple holes in the crossmembers and using a couple long 5/16″ bolts to mock up the location for the bracket.

Having the bolts stick up above the crossmembers was going to cause me problems with the transmission tunnel top and console assembly, so I drilled the upper hole bigger and dropped shorter bolts into the bars. I don’t think this weakens anything in any way that is concerning.

With that done, I just re-assembled everything, and ziptied the cables up above the driveshaft. The brake works far better now, and there’s more clearance around the driveshaft. In a car with a solid rear, this wouldn’t be an option because of the driveshaft moving around, but in an IRS car, the driveshaft never moves, so there’s no chance of it hitting anything.

Another shot showing the assembly bolted in — the old bracket can be seen just above it in the photo.

I’m still waffling on the design of the console. I’m definitely leaning towards both a center console and a storage console/armrest between the seats. I’m still trying to determine if its better to use the aluminum trim as I’ve been planning in between, or build up a more “engineered” console that spans the length of the cockpit.

I’ve got at least three or four more days without snow where I can leave the Miata out of the garage, so hopefully I can make some progress this week on the console. I may have to mock up a couple options out of cardboard to get a sense of how I want it to go together.